BRC Mesh, short for British Reinforcement Concrete Mesh, stands as a pivotal element in modern construction and infrastructure development. Renowned for its structural integrity, durability, and versatility, BRC Mesh plays a vital role in reinforcing concrete, offering robust support across various construction projects.

Understanding BRC Mesh

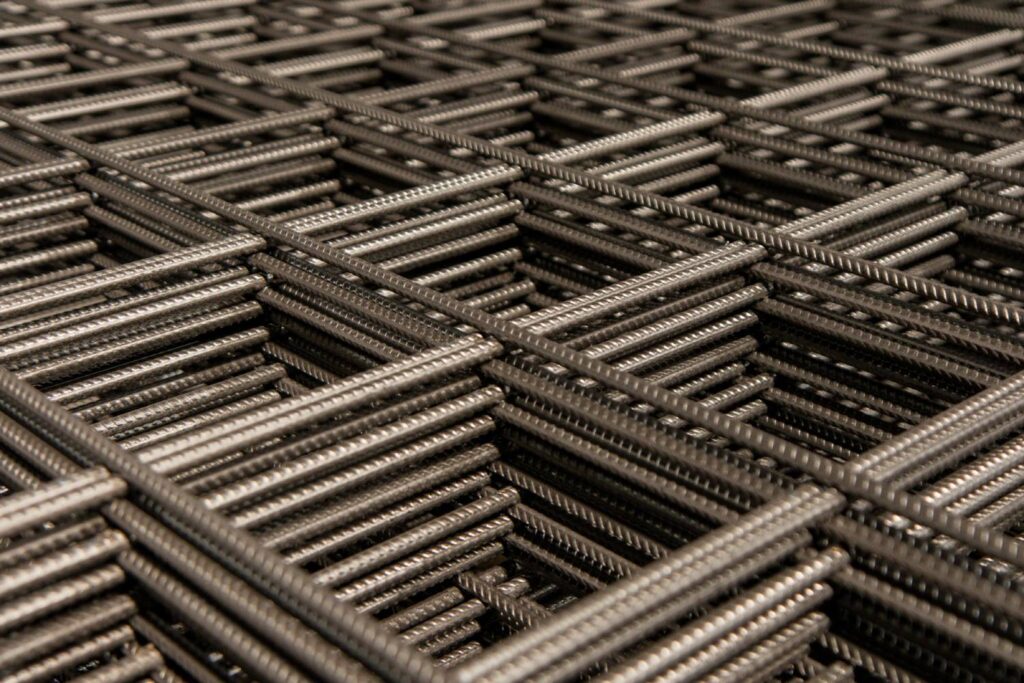

BRC Mesh is a steel reinforcement material composed of welded wire panels or rolls. Crafted from high-quality steel wires, it features a grid-like pattern of longitudinal and transverse wires, welded at intersection points, forming a mesh structure.

Reinforcement in Concrete Structures

BRC Mesh serves as a reinforcement within concrete structures. When embedded within concrete, it provides tensile strength, minimizes cracking, and enhances the structural integrity of walls, floors, foundations, and various concrete elements in buildings and infrastructure.

Versatility and Applications

The versatility of BRC Mesh extends to diverse construction applications. It finds use in residential, commercial, and industrial projects, including slabs, columns, beams, retaining walls, bridge decks, pavements, and other concrete structures.

Benefits of BRC Mesh

- Strength and Durability: BRC Mesh significantly reinforces concrete, improving its load-bearing capacity and longevity, thereby reducing maintenance needs.

- Crack Prevention: Its presence minimizes cracking in concrete, ensuring structural integrity even under heavy loads or seismic activity.

- Ease of Installation: Available in various sizes and configurations, BRC Mesh is easy to handle, cut, and install, facilitating efficient construction processes.

Types of BRC Mesh

BRC Mesh comes in different wire diameters, mesh sizes, and configurations, tailored to specific construction needs. Varieties include standard welded mesh sheets, high-strength deformed bars (HSDB), ribbed wires, and special meshes designed for particular applications.

Quality Standards and Compliance

Quality assurance is integral in the production of BRC Mesh. Manufacturers adhere to international standards and local building codes, ensuring that the mesh meets specified strength, weld quality, dimensional accuracy, and corrosion resistance requirements.

Environmental Impact and Sustainability

Efforts in sustainable production and materials recycling characterize the BRC Mesh industry. Manufacturers strive for eco-friendly production processes, and many meshes are made from recycled steel, contributing to environmental conservation.

Installation and Best Practices

BRC Mesh installation requires careful handling and proper placement to maximize its effectiveness. Following best practices in cutting, positioning, and securing the mesh within concrete structures ensures optimal reinforcement and structural integrity.

Industry Adoption and Innovations

The construction industry continues to embrace BRC Mesh due to its reliability and effectiveness. Ongoing research and technological advancements lead to innovations in mesh design, coatings for corrosion resistance, and improved installation techniques.

Conclusion

BRC Mesh remains an indispensable component in modern construction, reinforcing concrete structures and bolstering their durability and strength. Its versatile applications, compliance with standards, and continual innovations signify its pivotal role in shaping resilient and enduring infrastructure.

In essence, BRC Mesh stands as a testament to the engineering prowess and commitment to building robust, long-lasting, and sustainable structures in construction and infrastructure development.

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.